Browse Categories

Assembly Instructions

Bushing Assembly Instructions

ASSEMBLY

THE BEARINGS TAKE THE FORM AND FINAL SIZE AFTER FORCING THEM INTO THE APPROPRIATELY SIZED BEARING SEAT (WITH H7 TOLERANCE). IN ORDER TO EFFECT REGULAR ASSEMBLY, IT IS NECESSARY TO :

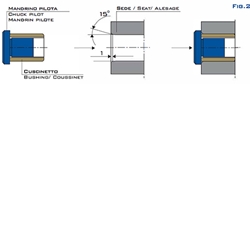

-USE A CHUCK PILOT TO INSERT A BUSH WITH THE CORRECT ALIGNMENT ACCORDING TO THE SEAT.

-OIL THE EXTERNAL SURFACE OF THE BEARING.

-CREATE AN APPROPRIATE CHAMFER ON THE SEAT (RECOMMENDED: 1mmx15°).

WHEN IT IS NECESSARY USE AN ADHESIVE TO GUARANTEE THE FIRM HOLDING OF THE BEARING TO ITS SEAT, IT IS RECOMMENDABLE THAT THE ADHESIVE DOESN’T TOUCH THE INTERNAL SURFACE OF THE BEARING AND IT MUST BE COMPATIBLE WITH THE ELEMENTS TO WHICH IT IS APPLIED. THE ASSEMBLY OF LARGE BEARING IS EASIER WITH THE USE OF CONTAINER RINGS WITH AN INTERNAL DIAMETER OF 0.1 mm BIGGER THAN THE EXTERNAL DIAMETER.

THE PRESSURE ON THE BEARING MUST BE CONTROLLED IN ORDER TO EFFECT FITTING ON ITS SEAT: IF THE BUSHING IS NOT OPTIMALLY ADAPTED TO ITS SEAT, IT COULDN’T WORK WELL. THE PRESSURE EXERCISED MUST BE IN ACCORDANCE WITH TABLE BELOW BECAUSE IT CAN GUARANTEE THE GOOD MATCHING.

|

BEARING THICKNESS 0,75/ 1,005mm |

F=300xL |

|

BEARING THICKNESS 1,5mm |

F=500xL |

|

BEARING THICKNESS 2,005mm |

F=700xL |

|

BEARING THICKNESS 2,5mm |

F=900xL |